Do You Really Need CORDURA®? Understanding Abrasion Resistance Fabrics for Workwear

- Gianni Romano

- Jul 28, 2025

- 4 min read

Updated: Jul 29, 2025

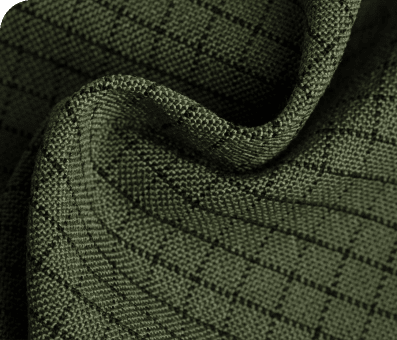

With respect to long-lasting workwear, a handful of brand names have become synonymous with durability, none more so than CORDURA®. Seen as the gold standard in abrasion-resistant textiles, CORDURA® fabrics are widely used in tactical uniforms, outdoor gear, and high-performance workwear.

But as cost pressures mount and sourcing teams explore circularity, it’s worth asking: do you always need CORDURA®, or are there viable alternatives?

This article explores the role of abrasion resistance in workwear: what it means, how CORDURA® works, when it makes sense to spec it, and when smarter sourcing strategies might yield the same results at a lower cost.

What Is CORDURA®?

CORDURA® is a registered trademark owned by Invista (a subsidiary of Koch Industries), used to describe a range of high-tenacity nylon and polyester-based fabrics engineered for strength, durability, and abrasion resistance.

The most common variants include:

CORDURA® Classic Nylon – Often made from air-textured 1000D or 500D nylon 6,6. Rugged, heavy-duty, and highly abrasion resistant.

CORDURA® Nylon 6,6 – Known for superior tensile and tear strength; commonly used in military and outdoor gear.

CORDURA® Polyamide/Cotton (Nyco) – A blend offering comfort and breathability while enhancing abrasion performance.

CORDURA® Recycled – A more recent offering using high-tenacity recycled polyester for brands targeting circularity goals.

Fabrics are subjected to rigorous internal testing by the brand, with abrasion ratings typically exceeding 300,000+ cycles on the Martindale test, a very extreme performance benchmark.

Why Abrasion Resistance Matters in Workwear

In industrial, outdoor, and tactical environments, abrasion is one of the most common causes of garment failure. Knees, elbows, cuffs, and shoulder areas are especially prone to friction, whether from equipment use, crawling, or general wear.

Abrasion-resistant fabrics are essential in garments that are:

Used daily in construction, logistics, or manufacturing

Worn in high-contact zones, like knee panels or reinforcements

Required to meet durability guarantees over long contract periods

Exposed to sharp edges, rugged terrain, or machinery

When a garment’s integrity depends on resisting wear and tear over time, abrasion resistance isn’t optional - it’s critical for performance, safety, and lifecycle cost.

When You Do Need CORDURA® Fabric for Workwear

There are times when nothing performs like CORDURA®, and it’s well worth the investment. CORDURA’s® blend of mechanical toughness, tear strength, and long-term abrasion resistance makes it ideal for:

Reinforcement zones: knees, elbows, seat patches, and shoulder yokes.

Tactical or military uniforms: where failure could mean injury or mission disruption.

Outdoor equipment: bags, belts, gloves, or areas exposed to the ground or harsh weather.

Premium brand positioning: where name recognition matters to end users or procurement leads.

In these cases, specifying genuine CORDURA® brings clear value - particularly when buyers demand long warranty cycles or when certification from a trusted supplier adds credibility.

When You Might Not Need It

Not all garments need to go toe-to-toe with rock, metal, or concrete.

CORDURA® is often over-specified, adding unnecessary cost, lead time, and in some cases, compromising recyclability. Situations where alternatives may be more suitable include:

1. Low-Friction Use Cases

In office-to-field uniforms, hospitality wear, or occasional outdoor use, standard polycotton or mechanical-stretch blends may offer sufficient abrasion tolerance without premium pricing.

2. Light-Duty Workwear

For jobs that involve minimal physical strain or where garments are replaced frequently, mid-tier synthetic or blended fabrics can meet the required durability levels without over-engineering.

3. Layering Strategies

If a garment is worn under a shell, the outerwear should carry the abrasion load, inner layers don’t need CORDURA®-grade protection.

What Are the Alternatives?

Sourcing teams looking to balance cost, function, and sustainability have several high-performance fabric alternatives to consider:

1. High-Tenacity Polyester (HTP)

Cheaper than nylon, and often sufficient for medium-duty use. When woven densely with a ripstop or oxford weave, HTP fabrics offer solid abrasion ratings with less cost and more recyclability.

2. Recycled Polyamide Blends

Some mills offer recycled nylon 6,6 fabrics that approach CORDURA®-like performance, especially when blended with stretch or reinforced coatings.

3. Mechanical Stretch Blends with DWR Finishes

Polyester blends with mechanical stretch and silicone-based DWR can perform well in lightweight uniforms, offering flexibility and resilience without premium fibre licensing.

4. Proprietary Fabrics from Mills

Many mills now offer their own fabrics similar to CORDURA® under different trade names, with similar Martindale scores. These often at a significantly lower cost and without brand licensing constraints.

Balancing Cost vs Function

When deciding whether to spec CORDURA®, brands should evaluate:

Expected wear zone and pressure - How much friction will it face?

Replacement cycles - Is the garment designed for daily use or occasional wear?

Total lifecycle cost - Is CORDURA® increasing lifespan enough to justify the cost?

Recyclability goals - Nylon/polyamide may limit mono-material strategies.

Brand perception needs - Will end users or procurement care about branded materials?

In many cases, a well-chosen blend, reinforced only where needed, can achieve 80% of CORDURA’s benefit at 60% of the cost.

How Lyfcycle Can Help

At Lyfcycle, we work with brands to match fabric selection with real-world requirements. We source CORDURA® fabrics when performance demands it, and guide clients through lab-tested, brand-free alternatives when budget or circularity are top priorities.

Get in touch to evaluate your options with sourcing experts who understand performance, cost, and impact.

Editor’s Note:

Invista (CORDURA®): Technical Specification Overview

Hohenstein Institute: “Martindale Abrasion Test Explained”

Textile Exchange: “Recycled Nylon and Polyester Performance Summary”

Workwear Gurus: “Fabric Durability in Industrial Clothing”

Schoeller Textil AG, Klopman, and Carrington Textiles: Proprietary abrasion-resistant fabric data

شيخ روحاني

رقم شيخ روحاني

شيخ روحاني لجلب الحبيب

الشيخ الروحاني

الشيخ الروحاني

شيخ روحاني سعودي

رقم شيخ روحاني

شيخ روحاني مضمون

Berlinintim

Berlin Intim

جلب الحبيب

سكس العرب

https://www.eljnoub.com/

https://hurenberlin.com/

https://www.blogger.com/profile/14805511932941819302

https://www.blogger.com/profile/00749959524029140964

جلب الحبيب بالشمعة

Capture urban cool with the Stussy 8 Ball Sherpa, a standout fashion essential. Pair it with the rugged Stussy Jacket 8 Ball to complete your streetwear wardrobe. Find both on the Stussy Jacket website.